This document describes how to identify defective RIK0138A Dual MCX Inserts shipped between April 2013 and July 2014. The subtle defect is due to a threaded MCX connector hole in the machined hardware not being deep enough, so that the connector can not reach the correct depth and the center conductor can not make a solid contact with the DIB board "tab". Only customers shipped RIK0128As after April 10th 2013 and before July 20th 2014 are notified.

SYMPTOMS

May cause connection or grounding issues between Top Plate and DIB Board when used with a QuickLock DIB interface. Other DIB board assemblies use additional screws that mitigate the affects of this defect by providing a good connection to the DIB.

IDENTIFYING DEFECTIVE INSERTS

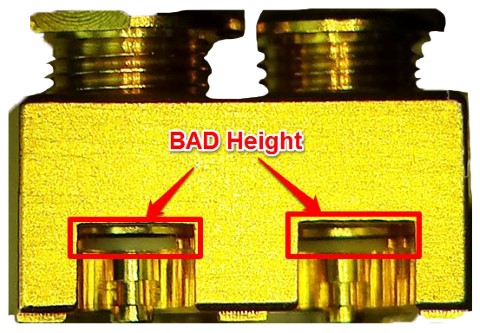

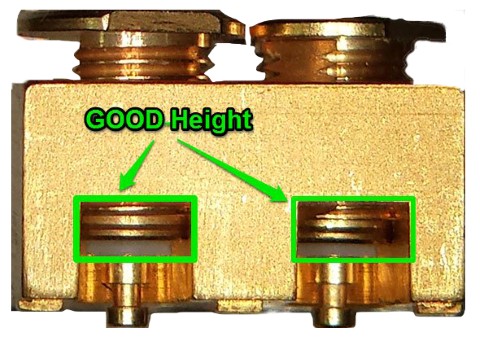

Center conductor sticks out is not low enough. Height can be inspected with the QuickLock DIB assembly removed and without disconnecting or unscrewing Insert from Fixture TOP Plate. Dial calipers can be used to inspect height to be between 0.008-0.015 inches over grounding squares as illustrated.

Center conductor sticks out is not low enough. Height can be inspected with the QuickLock DIB assembly removed and without disconnecting or unscrewing Insert from Fixture TOP Plate. Dial calipers can be used to inspect height to be between 0.008-0.015 inches over grounding squares as illustrated.

DEFECTIVE INSERT: Notice that threads are NOT visible.

CORRECT INSERT: Connector thread visible and contacts extend beyond grounding pads.

CORRECTIVE ACTION REQUIRED

If any defective Inserts are identified, replace each by unscrewing them from the Top Plate, disconnecting MCX cables, reconnecting cables to known good Inserts, then screwing the insert back into the Top Plate. Contact RI Support ([email protected]) to exchange defective units and return to RI Factory via standard RMA procedure.