NOTE: You should never do a final inspection of your own work.

Ensure the proper holes are threaded and counterbored as per CADKEY drawing W1MFBTW*. (* indicates the last letter of the part number and is typically the latest revision, ex.W1MFBTWG.)

Check to see that standoffs have been placed correctly according to CADKEY drawing W1MFBTW*.

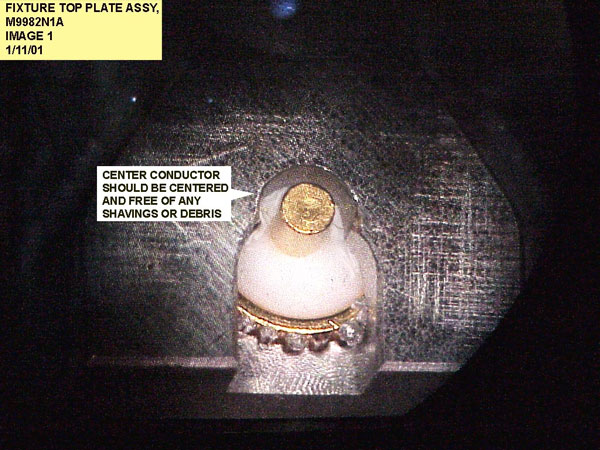

Inspection of SMAF press in connectors (PN M6MJ5W1A)

Verify that the areas between center conductors of the pressed in SMA connectors and plate are clear of any debris or shavings.(Use of a microscope is recomended for this check.)

Check height or "stick out" of center conductor end in relation to the bottom of the plate. Use a depth gauge for this check. The distance between the top plate metal and the center conducter should be => 8 and <= 15 mils measured in three places..

|

|

|

|